Today's boats require efficient propellers that perform

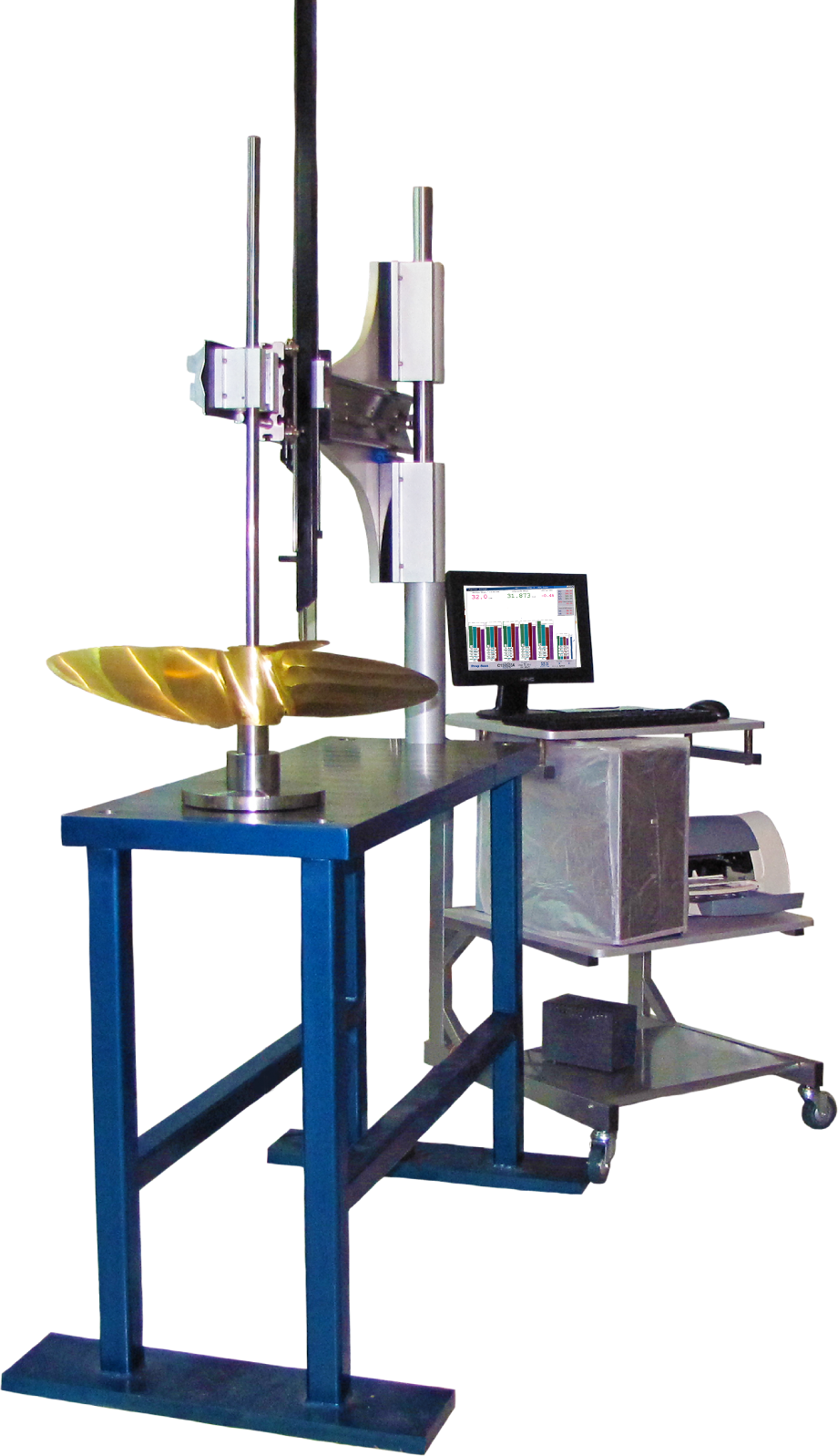

Prop Scan® / Hale MRI Tuning / TrueProp

Advantages of TrueProp, Prop Scan & Hale MRI Scan Systems

TrueProp, Prop Scan, Hale MRI are marine propeller inspection systems that enable propellers to be remanufactured, repaired and modified to extreme levels of accuracy. Inaccuracies in pitch, camber and section shape, which are important to a propeller's performance, is undetectable to the naked eye. The inaccuracies are detected through TrueProp, Prop Scan and Hale MRI scanning and provide AccuTech the data necessary to minimize vibration and slippage from the propeller.

- Advantages of Computer Measuring.

- Who Uses Computer Measuring and Inspection

- Industry Standards: ISO-484

- Propeller Problems

Advantages:

- Reduces fuel consumption

- Increases performance

- Increases speed

- Eliminates propeller induced vibration

- Enables synchronization of multiple engines

- Matches sets to ISO tolerances

- Ensures results are repeatable

Additionally, the PropExpert, Prop Scan and Hale MRI computer systems keep a record of all repairs. This allows technicians to reproduce a propeller of the same specification first time, every time.

Do you want a traditional propeller on your hi-tech boat?

Users of Prop Scan / Hale MRI / TrueProp

The following is a list of users in the marine world who have and continue to benifit from True Prop, Prop Scan and Hale MRI technologies.

- Recreational and Commercial Customers

- United States Coast Guard

- United States Navy

- Canadian Navy

- Australian Navy

- Propeller Manufacturers

- Boat Manufacturers

Prop Scan and Hale MRI have turned the old art of propeller repair into an exact science.

The International Organization for Standardization (ISO) is a worldwide federation of national standards bodies. This organization has produced 'ISO-484' that defines the standards of manufacturing tolerances for marine propellers. AccuTech technicians use this standard to inspect propellers and provides ISO compliance which gives you quality workmanship and peace of mind.

ISO-484 is categorized as follows:

Class Manufacturing Accuracy

- S= Very High Accuracy

- I= High Accuracy

- II= Medium Accuracy

- III= Wide Tolerances

Traditionally, classes 'S' and 'I' were only used on special vessels due to the extreme accuracy and precision. However, Prop Scan has made these classes available to all, providing economical resolution to everyone's propeller problems.

A Class of its Own: Due to Prop Scan's high levels of accuracy and repeatability it is now possible to repair a propeller to an accuracy level that is twice the accuracy of Class S. This classification is known as Class O.

Difficulties you may be having with your propeller :

Propeller Induced Vibration

Propeller induced vibration can be caused by inaccuracies in pitch, camber and section shape. Prop Scan allows us to see and remove these inaccuracies. This results in a smoother, more efficient and often faster propeller.

Tip Erosion

Abrasives present in the surroundings often cause tip erosion. Tip erosion reduces the overall diameter and performance of your propeller.

Propeller Cavitation

Propeller cavitation causes vibration, noise and serious damage to your propeller.

Cavitation problems must be split into two categories.

- Propeller induced cavitation.

- Vessel induced cavitation i.e. cavitation caused by appendages, hull shape and application.

If the cavitation is propeller induced, then Prop Scan technicians can measure your propeller and show you the cause of it.

Singing Propeller

Some propellers produce a high pitched noise at certain points between idle speed and full RPM. At the best of times this can be annoying, if this point lies spot in the middle of your cruising RPM it will be intolerable. Prop Scan technicians have the solution.

Propeller induced engine overload

If you are the proud owner of a beautiful yacht but you are a little embarrassed about the black smoke that is emerging from its transom, then it's time to do something about it. Overloading your engine will vastly reduce the overall life of this engine.

Propeller not loading the engine

When an engine revs higher than its recommended maximum RPM, it does not develop its maximum Horsepower. In other words you are not using your engine at its utmost capabilities. Most of the time this means there is additional speed to be gained.

Fuel Consumption

Does your boat consume more fuel than the recommended amount? The reason for greater fuel consumption is having a low classed propeller. On average, an ISO Class I propeller uses between 5-10% less fuel than a Class III propeller!

Propellers not synchronized

Many twin screw vessels have badly synchronized propellers, in other words the port and starboard engine are not loaded equally at maximum RPM. This is caused by pitch, camber and section shape differences between the two propellers.

Reversing problems

Reversing qualities are influenced by the position of your propeller and the section shape on the suction side of your propeller. If there is a suction section shape problem, technicians can locate it.

Poor propeller performance

Poor propeller performance can be caused by MANY different reasons. Incorrect propeller selection, poor propeller accuracy, etc.. Whatever it is there is now a way to find the problem.

Bring your propellers in and we will measure, and provide a Prop Scan or Hale MRI computer generated report of your propeller free of charge!